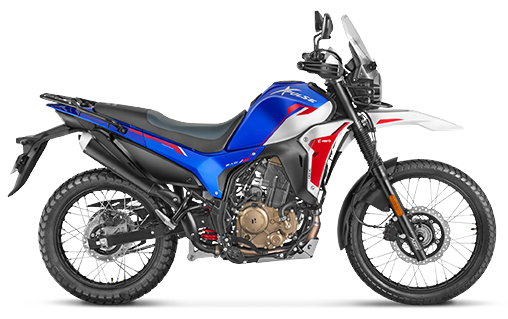

210 cc engine

A MISSION TO MAINTAIN HIGH ECOLOGICAL STANDARDS

At Hero MotoCorp we believe in sound and sustainable environmental practices.

Since inception we have cared for the environment by launching four stroke motorcycles in the era when two stroke two wheelers were popular.

In this endeavor we have always been blessed and guided by our Chairman Emeritus Dr.BrijmohanLal that "We must give back to the society from whom we generate our wealth".

As leaders in the automotive industry, we fully realized our responsibility to the fast changing industrial environment and understand our role in Sustainable Development of the Nation.

Hero MotoCorp has introduced Green initiatives in the organisation in Product Development, Manufacturing, Supply Chain and all the functions. At Hero we have taken several initiatives to reduce Carbon, Water & Waste footprint.

Our recent plants, such as the Vadora Manufacturing Plant, GPC, Neemrana and HGCIT facility in Jaipur, are IGBC certified and Neemrana is Hero's one-of-a-kind "garden factory". The Garden Factory showcases HMCL's environmental objectives, from the energy-efficient building envelope to the Big Foot air handlers to water and energy optimization.

Green Roof

Hero's green roof helps to conserve energy by moderating the temperature on the roof and within surrounding areas. It also helps to reduce the storm water runoff volume and peak flow rate dramatically. The green roof can restore aesthetic and ecological value of open urban spaces. In addition to this, it protects conventional roofing systems by doubling the service life of the underlying waterproof membrane.

Green Bio walls and Green Houses

Our latest plants Green Houses with Green Roof, are equipped with Hydroponics technology, which needs only 2% as much water as traditional farming. We improve photosynthesis by recycling carbon dioxide into the greenhouse. The oxygen produced by the green walls improves the working environment.

Sewage Treatment Plant

Hero ensures that sewage is biologically treated to attain efficacy. The wastewater from this treatment facility (STP) is recycled into soft water that is used in cooling towers and for horticulture purposes.

Zero Liquid Discharge Plant

To prevent water pollution, Hero has also invested in an Effluent Treatment Plant which is capable of treating waste water that contains degreasing chemicals, acidic/alkaline nature, plating waste, heavy metals and waste oil that is generated out of processes. The Waste water is either re-used in general activities or recycled back to processes with help of reverse osmosis process and multi effect evaporators thereby reducing the fresh water foot print. We recycle 90% of our waste water back to the process using Zero liquid discharge platform. Balance 10% is being reused for horticulture activities.

Rain Water Harvesting

All our plants are equipped with efficient rain water harvesting system which captures the rain water runoff and recharged into the aquifer thereby improving the ground water levels. The Rain Water Harvesting scheme extend up to the surrounding community and villages with an objective to control the rain water runoff, maintain ground water levels hence improve water security and minimize water logging / flooding with total rain water harvesting potential of 32.8 lakhs cubic meters which is much more than annual water requirement.

Waste Food Recycling

Hero ensures hygienic disposal of municipal waste through its organic waste converter, which in turn generates manure. This waste goes through 15 minutes of treatment and is then homogenized which is odour free. It is turned into compost in the next two weeks and finally is available for landscaping and greening applications. The waste treatment helps in preventing generation of methane which has 25 times more global warming potential as compared to CO2.

Paint Conservation

Along with preventing water pollution, Hero MotoCorp does its very best to prevent releasing pollutants in the air as well. The company is gradually adopted advanced robotic water based painting system which improves paint transfer efficiency. Our latest Vadodara plant is provided with a unique feature of VOC control in the paint shop using the concept of Regenerative Thermal Oxidizers (RTO) to treat the VOC before letting the emission into the environment.

Energy Conservation

- The Dharuhera plant has implemented several energy conservation projects, including compressor efficiency improvements (KWh/CFM), resulting in savings of 2,500 units per day.

- Non-fossil-fuel-based power – The Company’s solar footprint has increased to 11.2 MW with the potential of generating 12 million units annually.

- The CIT has adopted loss elimination techniques and technology improvements in the centralized air handling systems and adiabatic pad installations, resulting in annual savings of 1.5 lakh per unit.

- The Haridwar plant has improved energy efficiency by adopting process estimation and energy-efficient equipment, resulting in annual savings of 9 lakh per unit.

- The Neemrana plant has undertaken process optimization and improvements in compressed generation and variable frequency drive optimization, resulting in savings of 2,930 units per day.

- The Vadodara plant has implemented a project on improving the comfort cooling system, hot water generator operation optimization and compressed air system, resulting in savings of 4,600 KWh/day.

- The Chittoor plant has introduced the Smart Utility Cockpit, a new way of working through the digitalization of utilities by creating a central cockpit for effectively managing and controlling plant utility operations.

We care for the environment

We care for the environment

Angola

Angola

Argentina

Argentina

Bangladesh

Bangladesh

Bolivia

Bolivia

Colombia

Colombia

Costa Rica

Costa Rica

Dominican Republic

Dominican Republic

DRC

DRC

Ecuador

Ecuador

El Salvador

El Salvador

Ethiopia

Ethiopia

GCC

GCC

Guatemala

Guatemala

Guinea

Guinea

Guyana

Guyana

Haiti

Haiti

Honduras

Honduras

Kenya

Kenya

Madagascar

Madagascar

Mexico

Mexico

Myanmar

Myanmar

Nepal

Nepal

Nicaragua

Nicaragua

Nigeria

Nigeria

Panama

Panama

Peru

Peru

Philippines

Philippines

South Africa

South Africa

Sri Lanka

Sri Lanka

Tanzania

Tanzania

Trinidad

Trinidad

Turkey

Turkey

Uganda

Uganda

Zambia

Zambia